What is a Mezzotint?

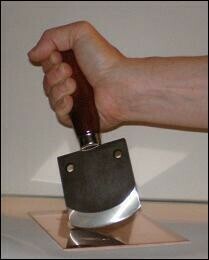

The technique generally involves first covering the surface of a metal plate (typically copper) with a dense texture of indentations using a tool called a rocker. The rocker has a flat, curved, fine-toothed steel blade, and a handle.

Rocking a copper plate.

Rocking a copper plate.

While held almost vertically, teeth down on the plate, the rocker is rocked back and forth. During rocking, the rocker naturally drifts across the surface of the plate. Multiple passes are done in this fashion until the entire plate is covered in an even layer of burrs.

If inked at this stage the plate would print a solid black. To create the image, the artist smooths select areas of the plate using tools such as burnishers and scrapers. The smoother an area, the less ink it will hold, and the lighter it will print.

A Very Brief History

A German soldier named Ludwig von Siegen is credited with developing mezzotint in 1642 as a means of reproducing paintings as prints for mass appeal. The use of mezzotint for this purpose became popular, especially in England, until the invention of photography; by the early twentieth century, mezzotint had largely disappeared as a reproductive process.

During the mid-twentieth century however, mezzotint was revived as a fine art medium. Artists such as Yozo Hamaguchi of Japan and Mario Avati of France adopted, innovated, and inspired others in the medium. Carol Wax is an American mezzotint artist who has written an authoritative book on the subject (Mezzotint: History and Technique).

Making a Mezzotint

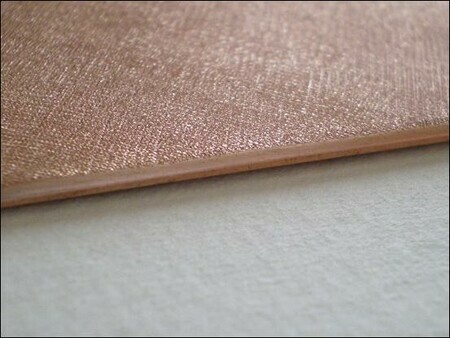

A three-by-four inch copper plate. The edges are beveled before beginning platework to help avoid damage to the rocker teeth during rocking. (Beveling also protects the press blankets from being cut by sharp plate edges during printing.)

A three-by-four inch copper plate. The edges are beveled before beginning platework to help avoid damage to the rocker teeth during rocking. (Beveling also protects the press blankets from being cut by sharp plate edges during printing.)

Rockers.

Rockers.

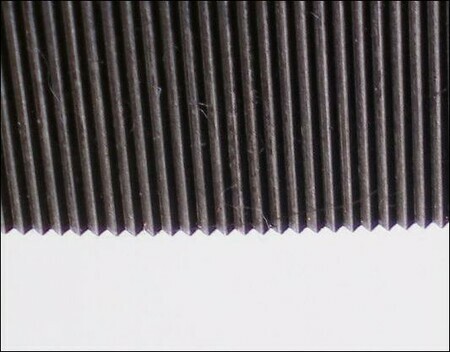

A closer look at the teeth of the middle rocker.

A closer look at the teeth of the middle rocker.

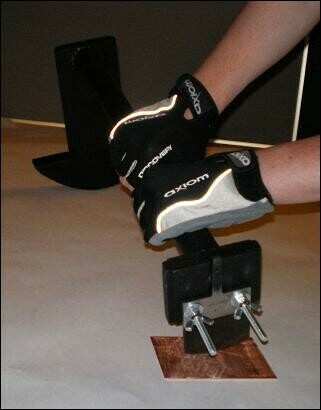

A handmade jig with which to rock more efficiently, being inspected. Here I have detached a rocker blade from its handle and attached it to the end of the pole.

A handmade jig with which to rock more efficiently, being inspected. Here I have detached a rocker blade from its handle and attached it to the end of the pole.

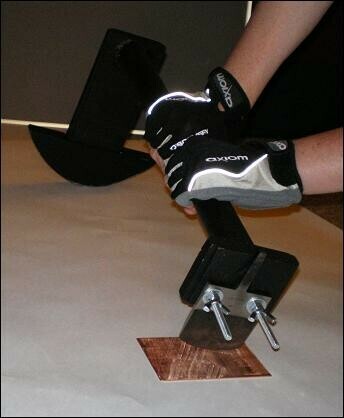

Rocking using the jig. The rocker blade naturally drifts across the plate surface with the rocking. Several passes in different directions are needed to create a dense texture of burrs which will be the starting point for creating the image on the plate. It takes me about five hours to rock a plate this size.

Rocking using the jig. The rocker blade naturally drifts across the plate surface with the rocking. Several passes in different directions are needed to create a dense texture of burrs which will be the starting point for creating the image on the plate. It takes me about five hours to rock a plate this size.

The plate once it has been fully rocked. This texture is called the ground. If the plate were to be printed at this stage, it would print a solid black.

The plate once it has been fully rocked. This texture is called the ground. If the plate were to be printed at this stage, it would print a solid black.  An assortment of tools. From left to right: drawing tool, for cutting plates; scraper, for creating smooth image areas; two roulettes, for creating stippled textures of dots on the plate; and three types of burnishers.

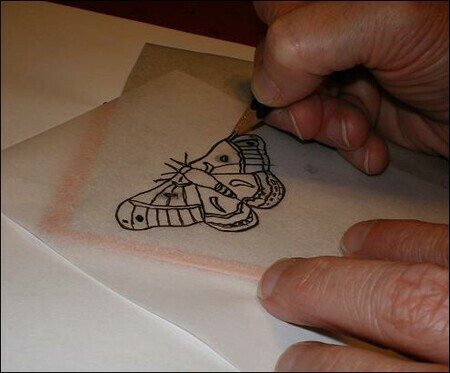

An assortment of tools. From left to right: drawing tool, for cutting plates; scraper, for creating smooth image areas; two roulettes, for creating stippled textures of dots on the plate; and three types of burnishers. Transferring the image using carbon paper.

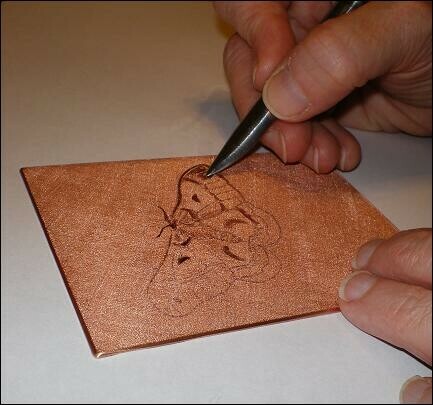

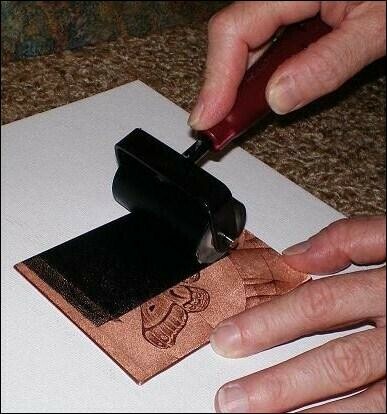

Transferring the image using carbon paper. Using a steel burnishing tool to polish smooth select areas of the plate.

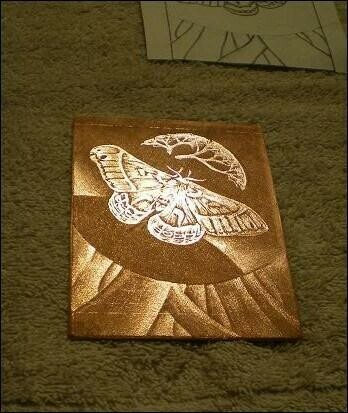

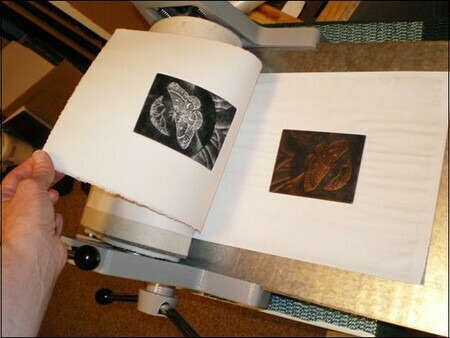

Using a steel burnishing tool to polish smooth select areas of the plate. The finished plate, ready for printing.

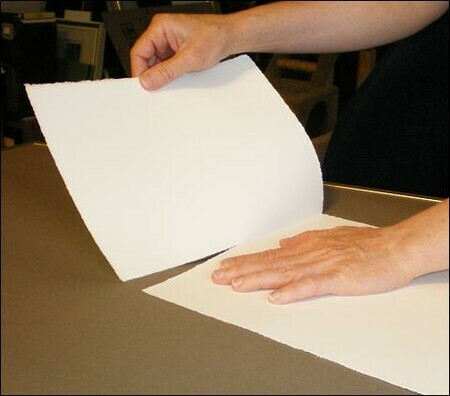

The finished plate, ready for printing. Tearing the paper to size. The sheets are then soaked in water and will be blotted just prior to printing. The paper is printed damp so that it will be soft enough that the pressure of the press will be able to push the paper down into the recessed (inked) areas of the plate.

Tearing the paper to size. The sheets are then soaked in water and will be blotted just prior to printing. The paper is printed damp so that it will be soft enough that the pressure of the press will be able to push the paper down into the recessed (inked) areas of the plate.  Rolling ink onto the plate with a small brayer. The intaglio ink is thick and greasy, and is forced into the texture of the plate with gentle pressure.

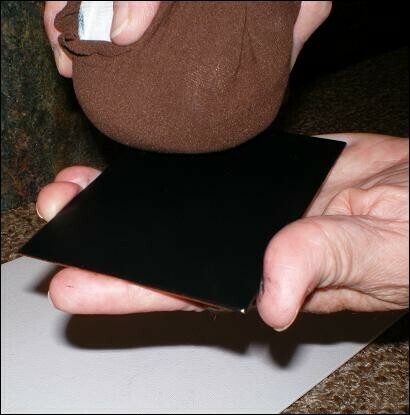

Rolling ink onto the plate with a small brayer. The intaglio ink is thick and greasy, and is forced into the texture of the plate with gentle pressure. Wiping the plate using a balled-up roll of fabric wrapped in a (lint-free) nylon. During wiping, ink is cleaned from the smoother areas of the plate but remains in the areas roughened by rocking.

Wiping the plate using a balled-up roll of fabric wrapped in a (lint-free) nylon. During wiping, ink is cleaned from the smoother areas of the plate but remains in the areas roughened by rocking. The wiped plate, ready to be printed.

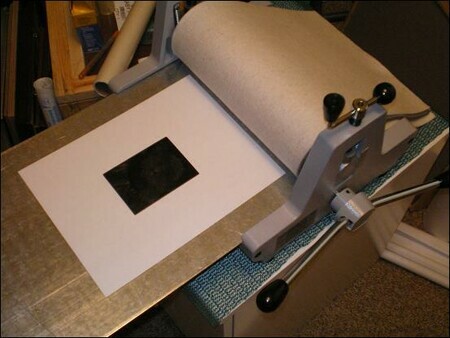

The wiped plate, ready to be printed.  The inked plate is placed face-up onto the bed of the press.

The inked plate is placed face-up onto the bed of the press. Placing the dampened paper onto the inked plate.

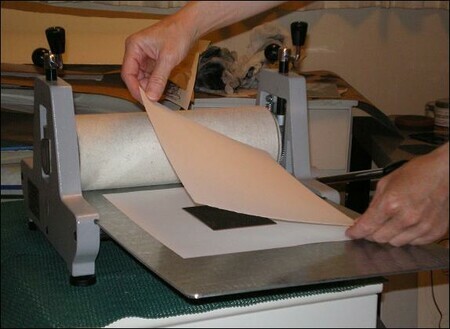

Placing the dampened paper onto the inked plate. Lowering the blankets. The blankets cushion the upper steel roller from the copper plate, and aid in pushing the dampened paper down into the recessed, inked areas of the plate during printing.

Lowering the blankets. The blankets cushion the upper steel roller from the copper plate, and aid in pushing the dampened paper down into the recessed, inked areas of the plate during printing. Turning the press handle to send the print between the rollers.

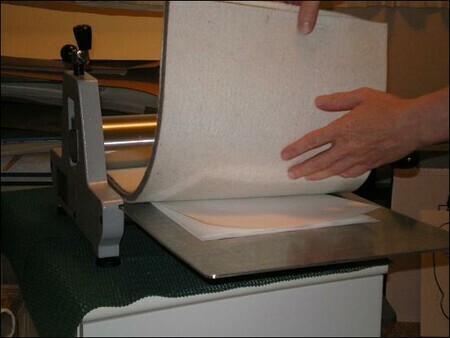

Turning the press handle to send the print between the rollers. The blankets are pulled back after printing.

The blankets are pulled back after printing. Pulling the print off the plate.

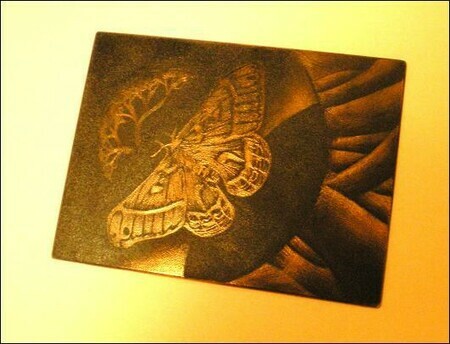

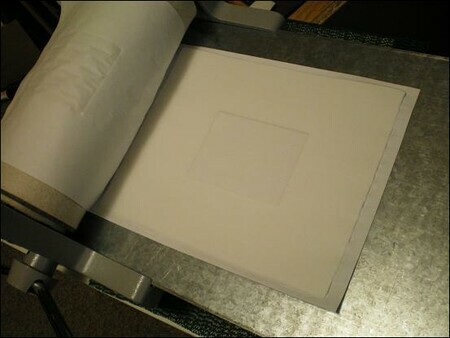

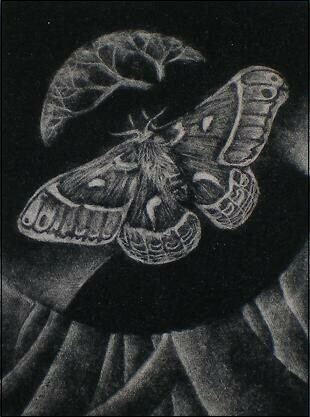

Pulling the print off the plate. The final result.

The final result.